Aviation must become more environmentally friendly – everyone agrees on that. Important aircraft manufacturers are therefore embarking on a course that the auto industry is already taking with electromobility. In fact, electrically powered propeller-driven aircraft have many advantages: fewer components in the drive system reduce maintenance, the time-consuming, loud and fuel-consuming warm-up on the ground is no longer necessary, small motors in the landing gear allow rolling without propellers – and in the air, electric motors deliver solid, consistently high performance with minimal noise. The disadvantage of power-powered aircraft, however, is the low energy storage capacity of the battery. Insufficient capacity for long distances, lengthy charging, susceptibility to failure at low and high temperatures, the required cooling of lithium-ion batteries to protect against overheating and explosion, and a limited number of charging cycles that limit the service life. Batteries contain numerous environmental toxins, are heavy and bulky and thus reduce the possible payload. The self-discharge of batteries is noticeable after months of idle time. And those who charge their electric aircraft during stopovers or on the move cannot rule out having to do so with “unclean” electricity from the socket.

Developing huge market potential with small aircraft

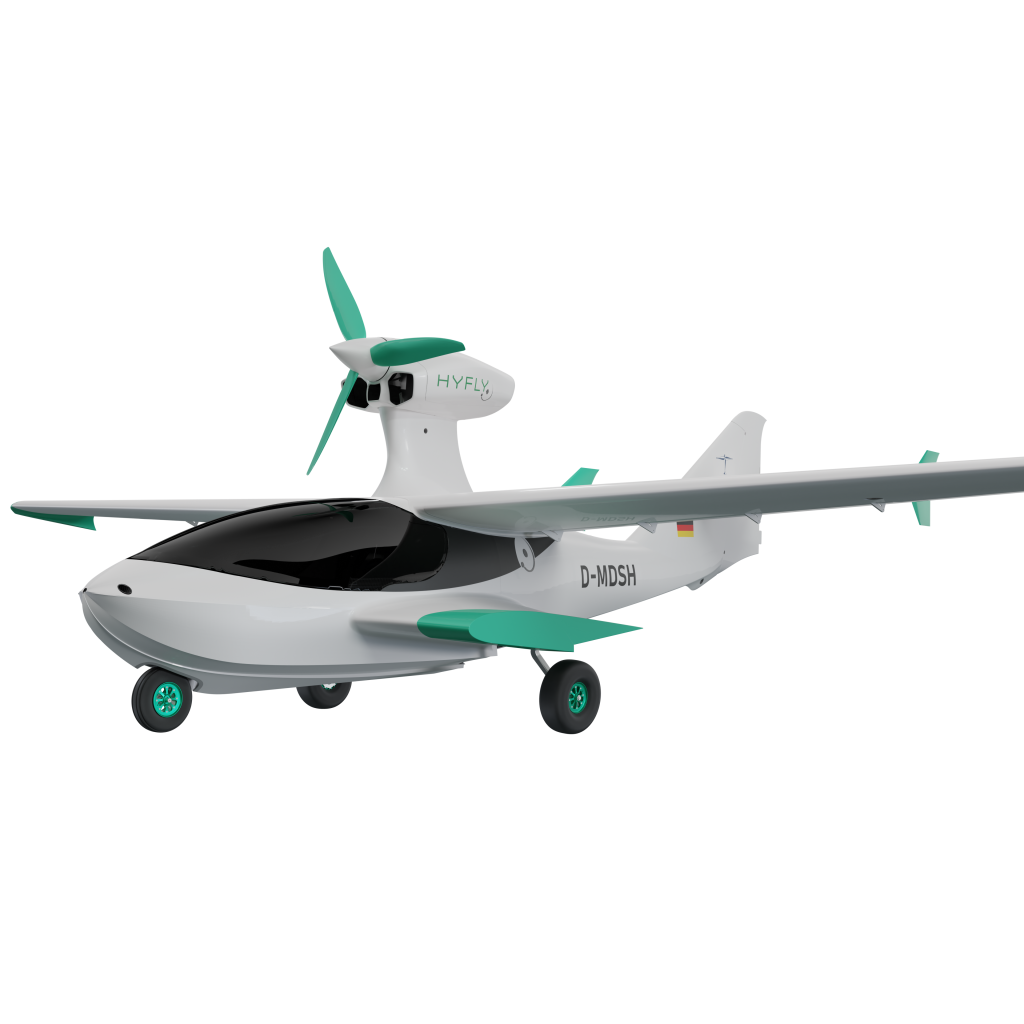

The electric hydrogen system from Kasaero and PS-HyTech solves many of these problems. PS-HyTech and Kasaero go one step further: They also prepare independent infrastructure facilities for small and large airfields to match their system. “Green hydrogen” is produced, stored and refueled locally on site.

German engineers see great potential for environmentally friendly drives in ultra-light and small aircraft that are affordable for many people. The “mass suitability” helps to increase the production quantities of new types of components and thus to reduce the purchase price. Experience can also be gained in order to scale future systems for larger aircraft, which as passenger transporters or freight machines have to meet significantly higher test and approval regulations. The PS-HyTech / Kasaero system can be integrated into various types of aircraft, does not change the outer contour of the aircraft hull and thus also does not change the aerodynamics – and thanks to its unprecedented low weight, it enables greater payloads than is possible today with battery-powered aircraft .

Would you like to find out more? Request information folder!